|  TUNNEL

REEDS TUNNEL

REEDS

Advantages

Advantages

High Quality Materials High Quality Materials

Suitable, reliable surface and creoss sectional conditions of the profile dents reduce contact resistance between the dents and the yarn. This enables higher standards of weaving. A dent choice between SUS301 and SUS420-J2 is made after considering your fabric type and usage.

Accurate Assembly Accurate Assembly

In order to produce high quality reeds, highly accurate assembly is indispensable. This has an especially vital relationship to the stability of weft insertion.

Air Flow Level Adjustment

Air Flow Level Adjustment

Based on our accumulated experience, we can offer the most suitable air flow for any combination of yarns, constructions and loom types.

Process for Dents (Option)

Process for Dents (Option)

DLC (Diamond-Like Carbon) Coated

DLC (Diamond-Like Carbon) Coated

DLC, with a surface hardness second only to diamond films, is an ultra hard (over HV 3000) coating, which prolongs reed life due to its smooth and unform surface, resulting in better selvedge quality.

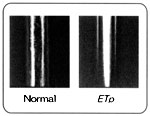

TR Original: ETpSurface Treatment TR Original: ETpSurface Treatment

The specially developed ETp treatment for tunnel dents greatly improves the smoothness and evenness of dent surfaces to levels hitherto unrealizable. The intensity of yarn contact levels is greatly reduced resulting in lower incidence of yarn damage. Smoother shed openings and longer reed life are just a few of the advantages offered by this Takayama original development.

*** Futher information aviable upon request. ***

|