| |

|

| |

|

| |

| |

|

| |

|

| |

|

| |

|

| |

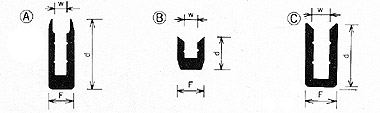

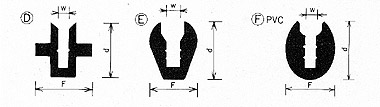

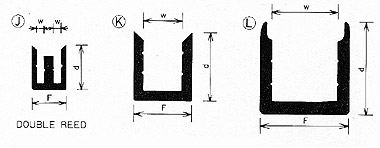

| Wire Width |

Thickness |

Height |

| W |

F.Fi |

d.di |

| C 2.2 mm |

4.8 mm |

12 mm |

| C 2.2 |

5.5 |

7 |

| C 2.2 |

8 |

18 |

| C 2.2 |

6 |

20 |

| C 2.2 |

5 |

9 |

| B 2.2 |

6.5 |

20 |

| A 2.2 |

6.5 |

18 |

| I 2.2 (SUS) |

4.8 |

20 |

| A 2.2 |

6.5 |

20 |

| J Double |

9 |

9 |

| J Double |

9 |

16 |

| H PVC Doube |

15 |

15 |

| A 2.5 |

7 |

20 |

| C 2.5 |

7 |

9 |

| C 2.8 |

6 |

7 |

| C 2.8 |

5 |

9 |

| B 2.8 |

8 |

10 |

| D 2.8 |

10 |

10 |

| C 2.8 |

5.5 |

12 |

| C 2.8 |

5.5 |

20 |

| C 2.8 |

5.5 |

25 |

| C 2.8 |

6 |

12 |

| C 2.8 |

6.35 |

26 |

| C 2.8 |

6.35 |

22 |

|

| Wire Width |

Thickness |

Height |

| W |

F.Fi |

d.di |

| E 2.2 mm |

15 mm |

17 mm |

| E 2.2 |

12.7 |

15 |

| C 2.8 |

8 |

20 |

| F 2.8 |

13.3 |

16 |

| C 4.0 |

8 |

8 |

| C 4.0 |

8 |

10 |

| C 4.0 |

8 |

12 |

| C 4.0 |

8 |

16 |

| C 4.0 |

8 |

18 |

| C 4.0 |

8 |

20 |

| C 4.0 |

8 |

30 |

| C 4.0 |

7 |

12 |

| E 4.0 |

15 |

17 |

| C 6.0 |

10 |

30 |

| C 6.0 |

10 |

25 |

| C 6.0 |

10 |

12 |

| H 6.0 |

15 |

16 |

| G 8.0 |

18 |

25 |

| C 9.5 |

12 |

12 |

| L 12.0 |

18 |

16 |

| L 12.0 |

18 |

20 |

| K 12.0 |

16.5 |

22 |

| L 12.0 |

19 |

20 |

| L 12.0 (SUS) |

18 |

20 |

|

| |

|

| |

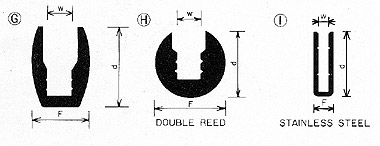

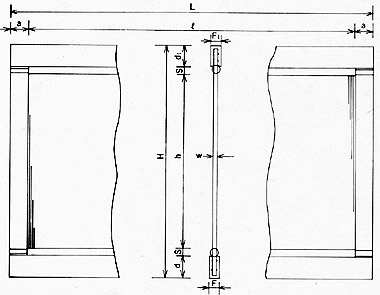

| L |

Total length |

| l |

Workable length |

| H |

Outside height |

| h |

Inside height |

| F.Fi |

Baulk thickness |

| a |

End piece |

| d |

Baulk height (Top) |

| d |

Baulk height (Bottom) |

| w |

Dentwire width |

| S |

Spring |

|

|

DURAFLEX

REED DURAFLEX

REED

The

well-known Duraflex Reeds are manufactured under continuous improvements,

always considering new weaving techniques and yarns, through the

efforts of the staff employed. We recommend the Duraflex Reeds for

all kind of high-speed weaving machines. The

well-known Duraflex Reeds are manufactured under continuous improvements,

always considering new weaving techniques and yarns, through the

efforts of the staff employed. We recommend the Duraflex Reeds for

all kind of high-speed weaving machines.

Characteristics Characteristics

Precision

spacing Precision

spacing

Perfect dent wire alignment is maintained

throughout the novel Duraflex assembly and bonding procedures. Using

a very low heat curing method guarantees against any expansion or

contraction of wires and frame during processing resulting in perfectly

spaced, straight wires bonded together without internal stresses.

Durability

Durability

The Duraflex reeds have just the right degree

of flexibility and resiliency to absorb the vibrations and shocks

transmitted during the weaving process. This shock absorbing characteristic

eliminates broken dent wires and results in longer life in and out

of the loom.

Lighter

weight Lighter

weight

The Duraflex bonding compounds are 8 times

lighter in weight than solder and the Duraflex construction allows

the use of light weight aluminum channels to replace the heavy steel

strips required by soldered reeds (the total weight is 2/3 than

soldered reeds). This lighter weight means less strain and power

requirement on all the driving parts of the loom.

*** Futher information aviable upon request. ***

|

|