| |

| |

|

|

|

| |

|

|

| |

|

| |

| Item |

Existing Comb |

Super Comb |

| Accuracy

(Pitch) |

O |

Unstable Positioning by Spacer |

@ |

Highly precise by exact processing |

| Joint Durability |

# |

Falling needles, problem at both edges |

@ |

Special design of ideal shape |

| Joint Accuracy |

# |

Hand made, Unstable by productin method |

@ |

micron level precision processing, stabilized accuracy |

|

| Joint Type |

TL |

Numbers of Needles |

Hight |

Tip |

Thickness |

| J

Type |

4 inch

|

20.25.35.40.45.50.55.60.65

.70.75.80 |

60

75

95

105 |

Round

Acute Round |

4 mm |

| 6 inch |

30.35.40.45.50.55.60.70

.75.80.90.100.110 |

| F

Type |

150 mm |

6 mm |

| 200 mm |

30.35.40.45.50.55.60.70

.75.80.90.100.110

.120.130.145 |

|

| Material |

Corrosion

Resist. |

Abrasion

Resist. |

Exchange

needle |

Piano

Wire

Cr - Plating |

# |

@ |

X |

SUS304

No - Plating |

@ |

O |

@ |

|

| |

| TL |

Min. |

Max. |

| 4

inch |

14 |

85 |

| 6 inch |

21 |

127 |

| 150 mm |

21 |

125 |

| 200 mm |

28 |

166 |

|

|

NCS NCS

What

is NCS ? What

is NCS ?

NCS is the next generation of numerical

controlled Comb design & manufacturing system, which offers

realization of distinguished

accuracy and application flexibility to the comb.

Super Comb is the first manufactured product

from NCS, which offers higher (NCS= New Comb System by Numerical

Contol)

Characteristics Characteristics

Fine

Design Fine

Design

Even arrangement of 1 needle at micron level, production is numberically controlled, and accuracy is maintained. Exact positioning of each warp creats excellent and stable warping beam.

Setting of expansion becomes easy and pitch accuracy is maintained at any area. Both edges of frame are processed by NC, and uniform and functional shapes are realized. To hod needles, instead of slit, pin-hole is used. This special shape holds needle nicely, and avoid needle drops and increase the contraction level.

- Accurate alignment of warp yarn stabilizes shape of beam and offers

high level of preparatory process.

- Pitch accuracy at the time of expansion and construction is improved

in all area because accuracy of every uint of the comb is improved.

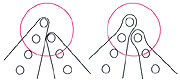

Round Shape

Round Shape

- Curvilinear processing by NC at both ends of frame enables uniform

accuracy and functional shape.

- Changing needle holding system from slit to pinhole and suitable

thickness of joint area improve

the strength of joint and prevent falling needle. Also, construction

level increases.

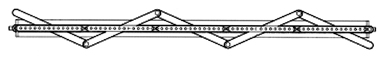

Real Straight

Real Straight

- By using "Super Expansion", the comb becomes 99.8% straight.

(Optional)

|

|