| |

|

| |

|

|

|

| |

|

| |

|

| Major Specifications |

| Ultrasonic Oscillator |

SHARP(Made in Japan) |

| Power Supply

Power Consumption |

AC100V (220~230V transformer included)

Maximum 250W |

| Ultrasonic Output

Output Frequency |

Maximum 100W

40 KHz |

| Heater Capacity |

100W |

| Washing Capacity |

Maximum 60 Sub-nozzles in 15 ~ 30 minutes (without metal block)

Maximum 6 - 16 Sub-nozzles in

15 ~ 30 minutes (with metal block) |

| Sub-nozzle holder speed |

10 RPM |

| Washing Timer |

Maximum Setting: 99 minutes

(Settings adjustable at one-minute intervals)

Temperature Setting 21°~ 60°

(Settings at or below 20°not possible) |

| Cleaning Basin

Water Volume |

SUS 304 grade stainless steel

250mm(w)×150mm(d)×100mm(h)

/ Approx. 3L |

| Exterior Dimensions / Weight |

280mm(w)×380mm(d)×380mm(h)

/ Approx. 6.5Kg |

|

| |

|

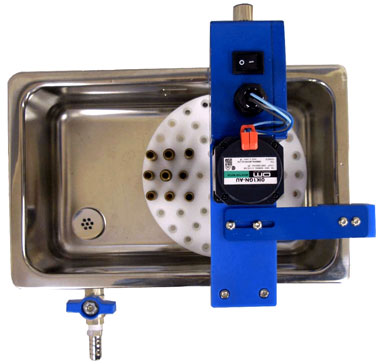

Ultrasonic Sub-Nozzle Cleaner Ultrasonic Sub-Nozzle Cleaner

TR-7500

Just place the sub-nozzles in the holes in the revolving holder, and dirt will be

washed away from the sub-nozzle tips automatically. Just place the sub-nozzles in the holes in the revolving holder, and dirt will be

washed away from the sub-nozzle tips automatically.

(The portion of the

sub-nozzles fixed with epoxy will not be damaged.)

Features Features

Ultrasonic cleaning washes away the minutest dirt. Ultrasonic cleaning washes away the minutest dirt.

Uneven washing is eliminated by the revolving holder in which the sub-nozzles are placed.

Uneven washing is eliminated by the revolving holder in which the sub-nozzles are placed.

Heating the cleaning fluid with the unit heater (included) results in more effective washing. Heating the cleaning fluid with the unit heater (included) results in more effective washing.

Duration of cleaning can be adjusted according to the severity of the sub-nozzles’ contamination.

Duration of cleaning can be adjusted according to the severity of the sub-nozzles’ contamination.

Up to 60 sub-nozzles (with no metal block) can be washed at one time. Up to 60 sub-nozzles (with no metal block) can be washed at one time.

(If there is a metal block, between 6 and 16 sub-nozzles can be washed at one time – exact number depending on the brand of the sub-nozzles being washed.)

A wash basket is included for the washing of various other types of machine parts.

A wash basket is included for the washing of various other types of machine parts.

|

|